Exploring Diverse Applications of the Best Flexo Printing Machine in Various Industries

The Flexo Printing Machine has emerged as a cornerstone technology in the printing industry, renowned for its versatility and efficiency across various sectors. According to the Smithers Pira report, the global flexographic printing market is projected to reach $20.63 billion by 2025, highlighting a significant growth rate driven by increased demand in flexible packaging, labels, and corrugated products. As industries strive for superior quality and sustainability, the advancements in Flexo Printing Machines, particularly from Chinese manufacturers, are setting new standards on a global scale. These machines not only optimize production processes but also enhance print quality and reduce waste, aligning with the industry's shift towards eco-friendly practices. Consequently, exploring the diverse applications of the best Flexo Printing Machines reveals their pivotal role in meeting the evolving needs of various industries, reinforcing China's position as a leader in manufacturing and exporting top-tier printing technology.

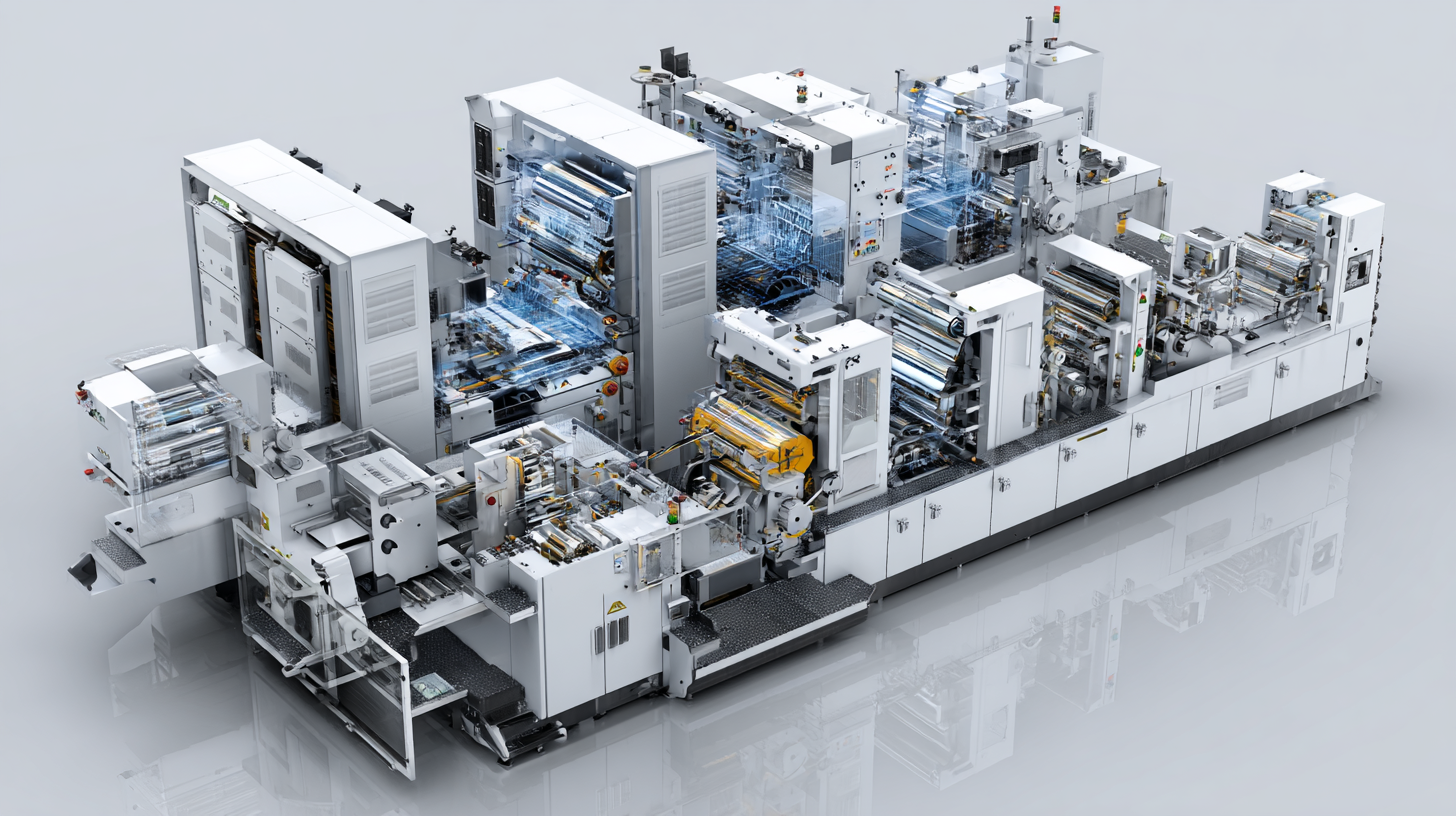

Exploring Flexo Printing: Key Features that Elevate Production Quality

The flexographic printing industry has witnessed remarkable advancements, particularly with the introduction of cutting-edge machines designed to elevate production quality significantly. As highlighted in recent market reports, the global flexographic printing machine market size was estimated at USD 2,828.5 million in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.0% from 2024 onward. This growth is largely driven by innovations that enhance efficiency, such as automation and eco-friendly plate technologies, which are helping businesses meet increasing demand for customized and sustainable packaging solutions.

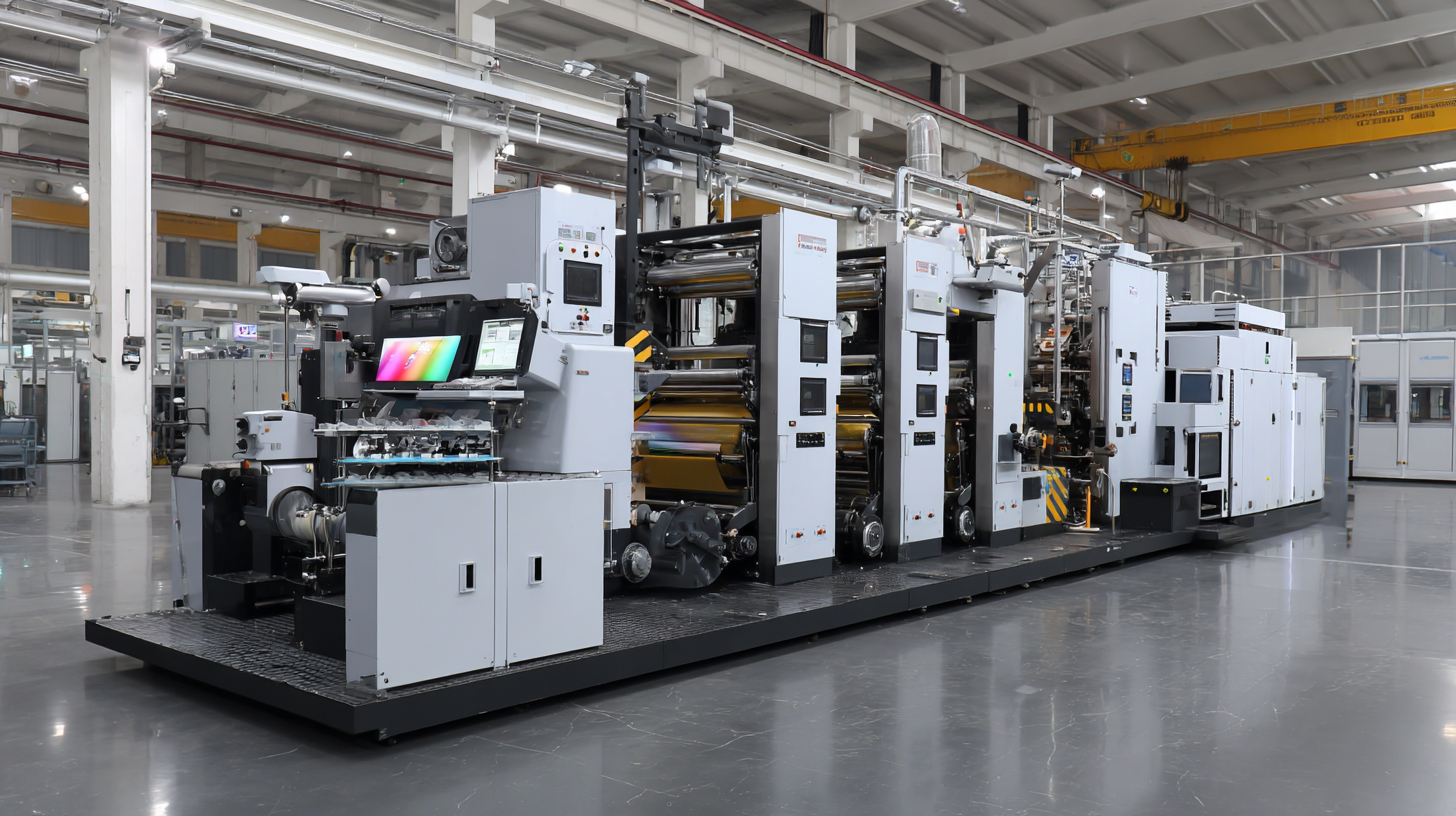

Key features of modern flexo printing machines include improved precision, versatility, and the ability to produce vibrant designs that capture consumer attention. The recent trend toward automation within the industry has simplified operations and attracted a new generation of workers, eager to engage with advanced technologies. Furthermore, major industry events like Labelexpo India 2024, set to be the largest edition yet, are poised to showcase these innovations, reflecting the ongoing commitment of manufacturers to enhance print quality and sustainability within various sectors, including labels and packaging.

Understanding Flexo Printing: Market Growth and Adoption Rates Across Industries

Flexo printing, known for its versatile application across industries, is witnessing significant market growth and adoption rates. According to a recent report by Smithers Pira, the global flexographic printing market is projected to reach $320 billion by 2025, reflecting a compound annual growth rate (CAGR) of 3.5% from 2020. This growth is largely driven by the increasing demand for flexible packaging solutions, particularly in the food and beverage sector where sustainability and efficiency are paramount.

Moreover, the adoption rates of flexo printing technology have surged in industries such as labels and packaging, where it accounts for approximately 40% of the market share. The trend towards eco-friendly printing processes has also propelled the use of UV and water-based inks, aligning with consumer preferences for sustainable materials. Data from the European Flexographic Industry Association indicates that investments in advanced flexo printing machinery have risen by nearly 20% in North America alone. This demonstrates a clear shift towards modernizing production capabilities to meet the evolving demands of a dynamic marketplace.

Case Studies: Flexo Printing's Impact on Packaging Efficiency in Consumer Goods

In the rapidly evolving landscape of consumer goods, flexo printing has emerged as a game-changer that enhances packaging efficiency. According to a recent Smithers Pira report, the global flexo printing market is projected to reach $500 billion by 2027, driven by its versatility and cost-effectiveness. Case studies highlight how major brands have leveraged the capabilities of the best flexo printing machines to optimize their packaging processes. For instance, a leading beverage company reported a 30% reduction in production waste after switching to flexo printing, due to its faster drying times and lower ink consumption compared to traditional printing methods.

Moreover, the impact of flexo printing on packaging design cannot be overstated. A study by the Packaging Association found that products utilizing flexo-printed packaging saw a 25% increase in shelf appeal, directly correlating to higher sales. This is particularly crucial in the competitive consumer goods market, where packaging plays a vital role in attracting consumer attention. Brands like Coca-Cola and Unilever have adopted flexo printing techniques to produce vibrant, detailed graphics that resonate with consumers, thereby improving brand loyalty and market share. By integrating advanced flexo printing technology, companies not only enhance their packaging efficiency but also elevate their overall product visibility in a crowded marketplace.

Impact of Flexo Printing on Packaging Efficiency in Consumer Goods

Sustainability in Printing: How Flexo Machines Contribute to Eco-Friendly Practices

Flexographic printing, commonly referred to as flexo printing, has evolved significantly, especially in its contribution to sustainability. As industries increasingly prioritize eco-friendly practices, flexo printing machines have emerged as leaders in helping reduce environmental impact. According to the Sustainable Packaging Coalition, nearly 73% of consumers are willing to pay more for sustainable packaging, driving the demand for greener printing processes. Flexo printing employs water-based inks and has a lower energy consumption compared to traditional printing methods, making it a more environmentally friendly option.

Tips for businesses looking to embrace sustainability through flexo printing include sourcing recyclable materials and partnering with suppliers that prioritize eco-friendly practices. Also, consider investing in modern flexo printing machines that utilize advanced technology for reducing waste, such as anilox rollers, which optimize ink transfer and minimize oversaturation.

Furthermore, the shift towards sustainable practices in flexo printing is supported by recent data from Smithers Pira, which indicates that the global flexographic print market is projected to grow at a CAGR of 3.5% from 2021 to 2026. This growth is largely attributed to the sector's adaptability and commitment to sustainable innovations. Implementing these changes not only benefits the environment but also meets the rising consumer demand for responsible production, ultimately enhancing brand image and loyalty.

Technical Innovations: Future Trends in Flexo Printing Technology and Their Implications

The flexo printing industry is undergoing significant changes, driven by a wave of technical innovations that promise to redefine printing processes across various sectors. One of the foremost trends is the adoption of digital integration within flexo printing machinery. This allows for harmonized workflows that enhance efficiency, reduce waste, and provide rapid turnaround times. With the increasing demand for short-run production, the shift towards digital print capabilities within flexo machines caters to the needs of businesses seeking flexibility and customization in their packaging and labeling solutions.

Another crucial advancement is the development of advanced ink formulations that improve print quality and sustainability. New eco-friendly inks and coatings are not only aligned with global environmental standards but also enhance the durability of printed materials. Furthermore, advancements in anilox roll technology and plate-making processes are elevating print resolutions and color accuracy. These innovations not only lead to more vivid and precise prints but also ensure that flexo printing remains competitive against other printing methods. As industries continue to evolve and embrace these technological improvements, the future of flexo printing appears both bright and promising.