What is a Robot and How Do We Define It?

Defining a robot is not straightforward. At its core, a robot is a machine designed to perform tasks autonomously. But how do we define robot beyond this basic idea? Different fields see robots in unique ways. In manufacturing, they may be seen as automated arms. In service, they might be friendly assistants.

To define robot, we must consider both physical attributes and functions. Robots can be programmed to learn and adapt. They can simulate human-like actions or even operate in hazardous environments. Yet, this flexibility raises questions. Can something without consciousness truly be called intelligent?

Despite advances in technology, there are imperfect aspects of our definitions. Many machines perform robot-like tasks without fitting the strict criteria. Too often, we may accept a broader scope of what makes a robot. Ultimately, as technology evolves, so will our understanding of what defines robot.

What Constitutes a Robot? Understanding Definitions and Classifications

Robots are fascinating machines that perform tasks autonomously. The definition of a robot often sparks debates among experts. Generally, a robot is considered a mechanical system capable of sensing, thinking, and acting. However, not all machines meet these criteria. Simple devices, like a programmable washing machine, might not classify as robots.

In understanding what constitutes a robot, it helps to explore various classifications. There are industrial robots, designed for repetitive tasks, and service robots, which help in daily activities. Yet, the line can blur. Some machines blend functions, complicating the classification. Autonomous vacuum cleaners exhibit traits of both types, raising questions about their classification.

Defining a robot isn't straightforward. Even within academic circles, disagreements persist. Is a drone a robot? Opinions vary. This complexity invites reflection on our relationship with technology and the evolving nature of robots. As innovations continue, we may need to reevaluate our definitions.

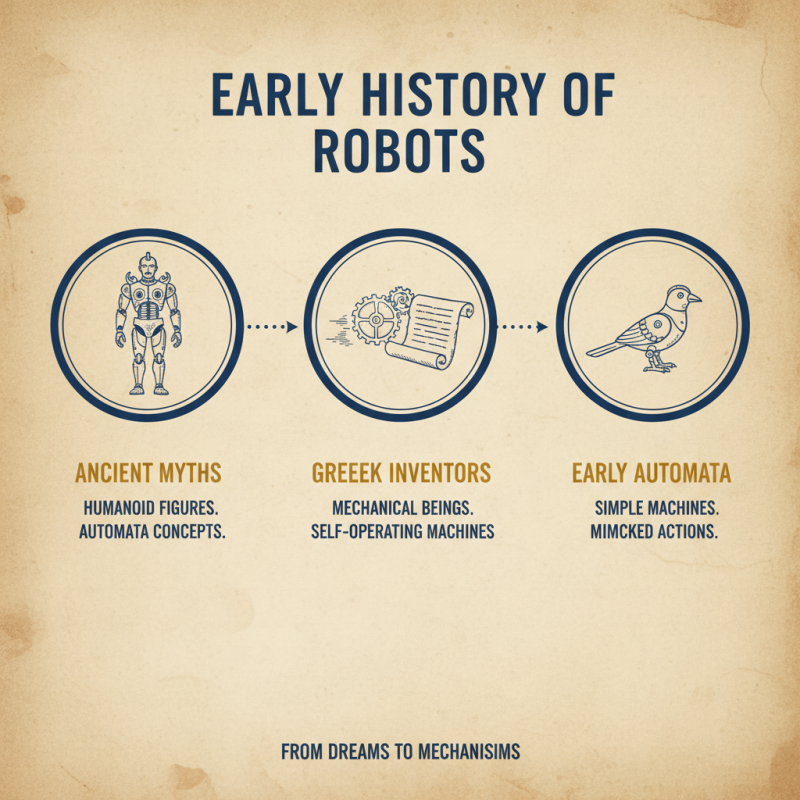

Historical Evolution of Robots: From Concept to Modern Implementation

The history of robots is fascinating. It began ancient times with myths and simple machines. Early ideas focused on automata—self-operating machines that mimicked human actions. Greek inventors envisioned mechanical beings, but these were just dreams.

In the 20th century, concepts started to come alive. With the advent of electricity and computing, robots began to evolve. Simple tasks like lifting objects in factories were their first roles. Early industrial robots were limited and rigid. They could not adapt or learn. Many failed to perform efficiently.

Modern robotics has taken significant leaps. We now have machines that can navigate complex environments. They use sensors and artificial intelligence to interact with humans. However, ethical considerations are vital. Who controls these machines? What happens when they malfunction? These questions remain unresolved, posing challenges to future advancements. Our journey with robots is just beginning, and much reflection is needed as we proceed.

Key Components of Robots: Sensors, Actuators, and Control Systems

Robots are becoming integral to various industries. Three key components define them: sensors, actuators, and control systems. Sensors allow robots to interact with their environment. They gather data about obstacles, temperature, and movements. For example, the global market for sensors in robotics is projected to reach $60 billion by 2026, showcasing their critical role.

Actuators translate sensor data into physical movement. They are the muscles of the robot, enabling actions such as lifting or moving objects. In 2022, the actuator market was valued at approximately $30 billion and is expected to grow significantly. This growth reflects the increasing demand for precise motion and control in robotics.

Control systems are the brains, managing the robot’s operations. They process information from sensors and command actuators. Many robots require complex algorithms to function effectively. However, the reliance on these systems can lead to challenges. High complexity can result in errors, causing malfunctions. Despite advancements, the robot's ability to adapt in unpredictable environments remains limited. Industry professionals often debate how to improve this adaptability for real-world applications.

Applications of Robotics in Various Industries: Statistics and Trends

Robotics is transforming industries with remarkable speed. In manufacturing, robots increase productivity and efficiency. They work alongside humans, handling tedious tasks. This partnership allows workers to focus on creative problem-solving. The blending of human skills and robotic precision is essential in any modern factory.

In agriculture, drones and automated machinery optimize processes. They monitor crops, spray pesticides, and harvest produce. These technologies contribute to sustainable farming but raise questions about reliance on automation. How will small farmers adapt to these changes? Meanwhile, in healthcare, robots assist in surgeries and patient care. They improve precision and reduce recovery times, yet pose challenges regarding human touch in medical settings.

The trends show significant growth. Statistics indicate that many sectors are investing in robotics. However, tech adoption often leads to job displacement. We must ask: is progress worth the cost to the workforce? A balance is necessary. Industry leaders should consider inclusive strategies to integrate robotics and support displaced workers.

Applications of Robotics in Various Industries

This chart illustrates the market share of robotics applications across various industries. Manufacturing leads with 30%, followed by Healthcare at 25%. Other sectors like Agriculture, Logistics, Construction, and Entertainment show emerging trends in adopting robotic technologies.

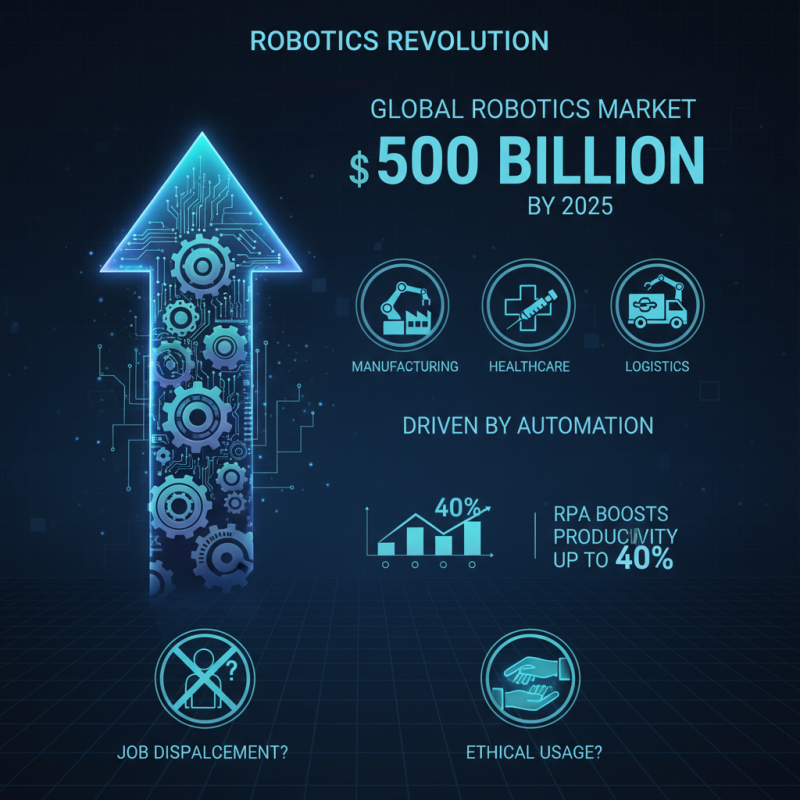

Future Trends in Robotics: Predictions Based on Current Industry Data

The field of robotics is evolving rapidly. Current industry data reveals that the global robotics market is expected to surpass $500 billion by 2025. This growth is driven by automation in various sectors, including manufacturing, healthcare, and logistics. For instance, the use of robotic process automation (RPA) has increased productivity by up to 40% in some businesses. However, while these statistics are impressive, concerns arise about job displacement and ethical usage.

Predictions indicate that collaborative robots, or cobots, will play a prominent role in the future. By 2030, it is estimated that over 30% of all manufacturing tasks may involve these machines. Cobots are designed to work alongside humans. Yet, the implementation of these technologies might come with pitfalls. Workers may feel threatened by the presence of robots in their workplaces, leading to resistance and tension. Additionally, the potential for errors in robotic systems raises questions about reliability and safety in critical areas like healthcare.

The robotic workforce is expanding, but challenges persist. Industry surveys show that 20% of automation projects fail to meet their objectives. Educating workers about robotics will be essential for future success. This includes not only technical skills but also an understanding of the ethical implications of robotic deployment. As we look ahead, it’s crucial that stakeholders address these issues for a balanced and productive relationship between humans and robots.

Related Posts

-

2026 How to Embrace Robot Technology for Future Innovations?

-

What Does a Robotics Technician Do and How to Become One?

-

2026 Top Trends in Robotic Automation You Should Know?

-

What is Robotics and Automation and How It Transforms Industries Today

-

2026 Best Robotics and Automation Trends to Watch?

-

How to Harness Robotics and Automation for Your Business Success?