Unlocking Efficiency: 7 Essential Specs of the Best Stretch Film Blowing Machine for Optimal Production

In the competitive landscape of packaging and manufacturing, the efficiency of production lines is paramount, and one key player in this domain is the Stretch Film Blowing Machine. According to a recent report by Smithers Pira, the global stretch film market is expected to reach a value of $12 billion by 2026, driven by the growing demand for protective packaging solutions. To capitalize on this trend, manufacturers must invest in advanced blowing machines that enhance productivity while ensuring quality outputs. Understanding the essential specifications of these machines is crucial, as it allows businesses to streamline operations and maintain high standards of production. This blog will explore the seven vital specifications of the best Stretch Film Blowing Machines, providing insights into how these features contribute to optimal manufacturing processes and compliance with industry standards.

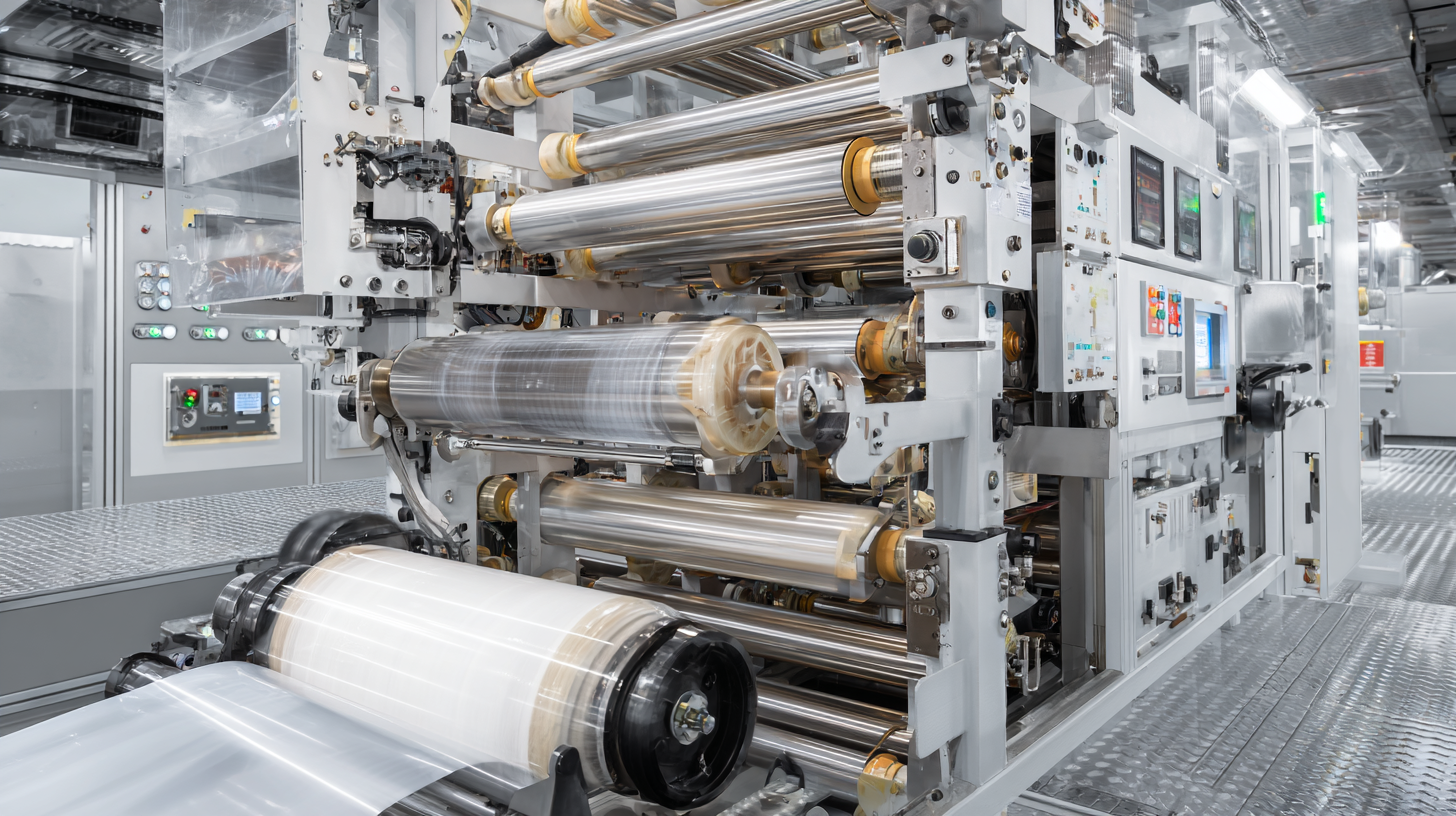

Understanding the Critical Role of Stretch Film Blowing Machines in Modern Packaging

In the fast-paced world of modern packaging, stretch film blowing machines play a pivotal role in ensuring efficiency and reliability. These machines are essential for producing high-quality stretch films that secure products during storage and transit, minimizing damage and waste. Their ability to create strong, stretchable films on a large scale makes them invaluable in various industries, from food and beverage to electronics and logistics.

Understanding the critical specifications of an effective stretch film blowing machine can significantly impact a company’s productivity. Key features such as blow-up ratios, film thickness control, and energy efficiency are vital for optimal production. By investing in advanced technology that offers precise control over these variables, businesses can enhance their operational efficiency, reduce costs, and improve the overall quality of their packaging solutions. As packaging demands evolve, selecting the right stretch film blowing machine becomes not just a choice but a strategic advantage in staying competitive in the market.

Key Specifications for Enhanced Production Efficiency in Stretch Film Blowing Machines

When it comes to enhancing production efficiency in stretch film blowing machines, key specifications play a crucial role. One of the most essential specs is the machine's output capacity. A high output capacity enables manufacturers to meet increasing demand without compromising on quality. Choosing a machine that can produce a significant volume of stretch film in a shorter timeframe allows for faster turnaround and improved productivity. This not only reduces lead times but also optimizes resource utilization.

Another critical specification is the blow-up ratio, which directly affects the thickness and strength of the film produced. A well-optimized blow-up ratio ensures that the stretch film has adequate stretchability and durability, which are vital for packaging applications. Additionally, features such as adjustable pre-stretching capabilities and energy-efficient designs contribute to lower operational costs while maintaining high-quality standards. By focusing on these specifications, manufacturers can unlock unprecedented efficiency and elevate their production processes to new heights.

Unlocking Efficiency: 7 Essential Specs of the Best Stretch Film Blowing Machine for Optimal Production

| Specification | Description | Importance |

|---|---|---|

| Blower Power | 15-30 kW motor for optimal film thickness | Higher power leads to better film quality |

| Die Diameter | 50-150 mm for various film sizes | Affects production speed and film texture |

| Production Speed | 80-200 m/min based on machine efficiency | Directly influences output capability |

| Film Thickness Range | 10-30 microns for optimal performance | Thickness affects strength and stretchability |

| Temperature Control | Advanced control systems for uniform heating | Ensures consistent film quality |

| Winding System | Automatic winding for easy handling | Improves productivity and reduces waste |

| Control System | User-friendly interface with automation features | Enhances operational efficiency and ease of use |

Analyzing Common Problems Faced by Manufacturers Utilizing Stretch Film Technology

The stretch film market has been witnessing significant growth, driven by the increasing demand for packaging solutions across various industries. According to industry reports, the global stretch wrap market is projected to expand at a compound annual growth rate (CAGR) of approximately 4.6% from 2021 to 2028. This growth can be attributed to factors such as the rising popularity of e-commerce and the need for efficient cargo protection during transportation. Notably, the market is segmented into cast wrap and blown wrap types, with blown wrap often preferred for its superior strength and puncture resistance, making it a common choice for heavier loads.

However, manufacturers in the stretch film sector face several challenges that can impede productivity. Common issues include machinery downtime, inconsistent film quality, and material wastage. These problems can stem from outdated equipment or inadequate understanding of the production process. A study indicates that nearly 20% of manufacturers experience regular equipment malfunctions, while issues related to improper film stretching can lead to up to 15% in material waste. Addressing these challenges requires a careful analysis of production techniques and the adoption of advanced technology to enhance efficiency and overall performance in stretch film production.

Unlocking Efficiency: Performance Analysis of Stretch Film Blowing Machines

Industry Insights: Benchmarking Stretch Film Blowing Machine Performance and Output

The stretch film market is poised for significant growth, with a projected value of US$ 4.1 billion in the near future. This surge is primarily driven by the increasing demand for efficient packaging solutions across various industries, including retail and logistics. As companies strive for optimal production, the performance and output of stretch film blowing machines become critical benchmarks for assessing operational efficiency.

Recent industry reports indicate that the Compound Annual Growth Rate (CAGR) for the demand for stretch films in Canada is expected to remain robust, reflecting an upward trend in manufacturing processes that prioritize sustainability and cost-effectiveness. To keep pace with this rising demand, manufacturers must invest in advanced stretch film blowing machines that embody essential specifications—such as high output capacity, energy efficiency, and precision in film thickness control. Such machines not only enhance production rates but also contribute to overall material savings, making them invaluable assets in an increasingly competitive market.

Utilizing advanced technologies in these machines can help businesses adapt to changing consumer preferences while also meeting stringent quality standards. By focusing on these critical performance parameters, companies can ensure they remain at the forefront of the packaging industry as the demand for stretch films continues to evolve.

Future Trends: Innovations Shaping the Stretch Film Blowing Machine Landscape

The future of stretch film blowing machines is being shaped by innovative technologies that cater to the evolving needs of the packaging industry. As the global pallet wraps market is projected to grow from USD 6.8 billion between 2025 and 2035, manufacturers are turning towards advanced machinery that enhances production efficiency. These machines are now designed to produce films that are not only lightweight and durable but also more sustainable, responding to the increasing demand for environmentally friendly packaging solutions.

In recent years, the flexible packaging sector has gained traction for its efficiency and functionality. However, challenges remain in recycling and environmental impacts, urging manufacturers to integrate greener practices in machine operations. Innovations such as enhanced film stretching capabilities and the use of bio-based materials are on the rise, aiming to win over both consumers and environmental advocates alike.

Moreover, the blow molded bottles market is witnessing significant trends with lightweight and cost-effective solutions leading the way. The integration of smart technologies and IoT in stretch film blowing machines is anticipated to further streamline production processes, reduce waste, and optimize material usage, ensuring that companies remain competitive in a fast-evolving landscape.