Understanding Industry Standards for Best Slitting Machine Selection and Usage Guide

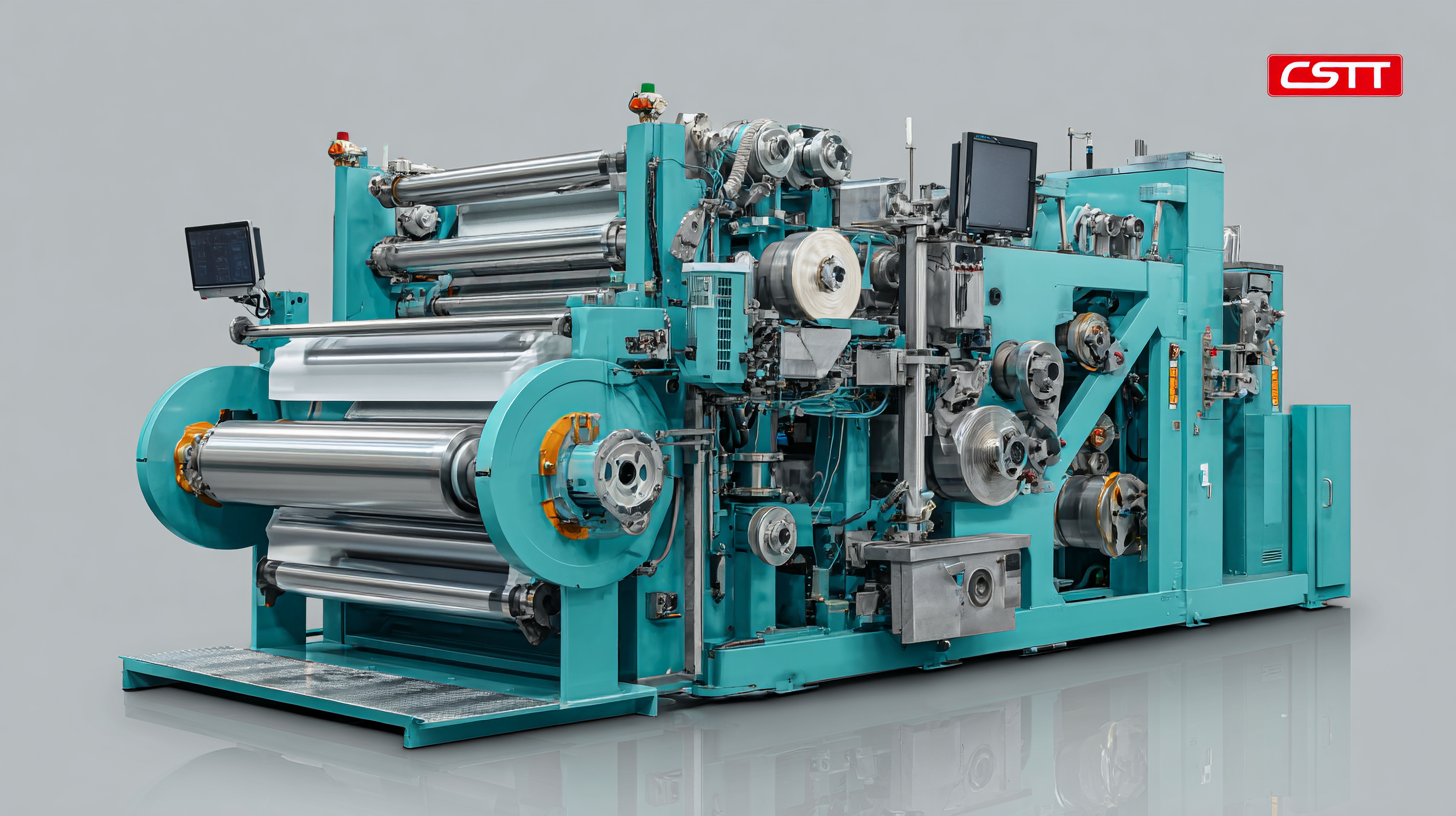

In the ever-evolving landscape of manufacturing, selecting the right Slitting Machine is crucial for optimizing production efficiency and maintaining quality standards. Understanding the characteristics and applicability of different product types is essential for effective slitting operations. This guide aims to provide clarity on industry standards and best practices when choosing and using slitting machines.

From paper and foam to metal and film, each material has unique properties that influence the slitting process. By exploring alternative types and their specific applications, manufacturers can make informed decisions that align with their production needs. Whether you're dealing with high-speed production lines or custom jobs, knowing how to select the right slitting equipment will not only enhance productivity but also ensure that you meet your customers' demands.

The Importance of Selecting the Right Slitting Machine for Efficiency and Quality

Selecting the right slitting machine is crucial for maximizing efficiency and maintaining the quality of finished products in various industries. According to a report by Smithers Pira, the global slitting machine market is projected to grow at a CAGR of 4.3% from 2021 to 2026, driven by increasing demand for precision in manufacturing processes. This highlights the importance of investing in high-quality slitting machines that can meet specific operational needs while adhering to industry standards.

Efficiency in production not only relies on the machinery itself but also on the proper selection of features that align with product requirements. A study by the Association for Manufacturing Technology states that optimizing machine settings can increase throughput by up to 25%. By choosing a slitting machine that incorporates advanced controls and automation, manufacturers can significantly reduce waste and rework, ensuring that each product meets required tolerances and quality benchmarks. Therefore, careful consideration during the selection process can lead to competitive advantages in both efficiency and product quality.

Analyzing Common Problems Encountered with Conventional Slitting Processes

When it comes to conventional slitting processes, industries often face various common challenges that can hinder efficiency and productivity. According to a recent report by IndustryWeek, approximately 30% of manufacturers experience delays due to improper alignment of slitting knives, leading to material waste and increased operational costs. This misalignment can occur due to inadequate machine settings or inconsistent material feed, ultimately affecting the quality of the finished product.

Additionally, the accumulation of slitting debris is a recurrent issue that many operators encounter. A study conducted by the Slitting and Rewinding Association indicated that up to 25% of production time can be lost in clean-up efforts, primarily caused by buildup on cutting edges. Such interference not only slows down the process but can also lead to damaged machinery, resulting in costly repairs.

These common problems underscore the necessity for manufacturers to adopt more efficient slitting solutions. By choosing advanced slitting machines equipped with state-of-the-art features like automatic knife positioning and debris management systems, operators can mitigate these challenges significantly, as highlighted in a comprehensive market analysis by Global Industry Analysts. This proactive approach not only optimizes production timelines but also ensures a higher quality of output in the competitive manufacturing landscape.

Understanding Industry Standards for Best Slitting Machine Selection and Usage Guide - Analyzing Common Problems Encountered with Conventional Slitting Processes

| Dimension | Value | Common Issues | Recommendations |

|---|---|---|---|

| Blade Type | Circular Blade | Blade Wear | Regular maintenance and timely replacement |

| Material Thickness | 0.5 mm to 5 mm | Uneven Cuts | Adjust tension settings appropriately |

| Slitting Speed | 50 m/min | Jamming | Monitor speed and feed rate |

| Machine Width | 1.5 m | Material Misalignment | Ensure materials are fed correctly |

| Lubrication System | Automatic | Overheating | Check lubrication levels regularly |

Key Industry Standards and their Impact on Slitting Machine Performance

When selecting a slitting machine, understanding key industry standards is crucial to ensure optimal performance. These standards often dictate the machinery's design, efficiency, and safety features, directly impacting production capabilities. For instance, compliance with ISO standards ensures that machines meet stringent safety and quality benchmarks, reducing the risk of malfunctions and enhancing overall reliability.

Tips: Always check for certifications that guarantee compliance with relevant industry regulations. This not only assures quality but also helps in maintaining high operational efficiencies.

Furthermore, industry standards such as those set by ASTM can influence the materials' compatibility that a slitting machine can handle. This knowledge allows manufacturers to choose the right machine based on the specific requirements of their materials, leading to improved cut precision and reduced waste.

Tips: Investigate the material specifications and consult with machine manufacturers to determine the best options available for your production needs. This proactive approach can significantly extend the lifespan of your equipment and optimize performance.

Best Practices for Maintenance and Operation of Slitting Machines

When it comes to the maintenance and operation of slitting machines, adhering to best practices is crucial to enhance performance and lifespan. According to a report by the European Machine Tool Industry Association, improper maintenance accounts for nearly 30% of machinery downtime. Regular inspections, including lubrication of moving parts and checking for wear and tear, can significantly curtail unexpected failures, leading to improved productivity.

Furthermore, operational efficiency can be greatly affected by the training of personnel. A study from the International Slitting Association indicates that properly trained operators can increase machine efficiency by up to 15%. Implementing standardized operating procedures and regular training programs not only ensures safety but also promotes a deeper understanding of the machine's capabilities, ultimately leading to better quality slitting results. Prioritizing these best practices is essential for anyone looking to optimize their slitting operations.

Evaluating the Cost-Benefit Ratio of Advanced Slitting Technologies

When evaluating advanced slitting technologies, understanding the cost-benefit ratio is crucial for making informed investment decisions. A report by Markets and Markets suggests that the global slitting machine market is expected to grow from $2.5 billion in 2021 to $3.2 billion by 2026, reflecting a growing demand for precision and efficiency in manufacturing processes. This growth indicates that manufacturers are increasingly recognizing the long-term savings and productivity enhancements that advanced slitting machines can offer, despite their higher initial costs.

In a recent case study, a leading packaging company implemented an advanced slitting technology that improved material yield by 15% and reduced waste by 10%. The investment paid off within 18 months, as the enhanced output and quality resulted in an estimated annual savings of $200,000. Manufacturers considering slitting machine upgrades should assess not only the purchase price but also the potential return on investment (ROI) through increased efficiency and reduced operational costs. Such evaluations can determine whether the initial expenditure aligns with long-term strategic goals in a dynamic market environment.