2026 Top Trends in Material Handling Robots for Efficient Warehousing

In the evolving landscape of warehousing, material handling robots are becoming indispensable. According to a recent study by the Robotics Industries Association, the demand for these robots is projected to grow by 25% annually over the next few years. This surge reflects the ongoing push for efficiency and productivity in supply chains worldwide.

Experts in the field have noted the transformative potential of material handling robots. “They are not just tools; they are catalysts for change in logistics,” says Dr. Emily Harrison, a renowned robotics expert. Her insights emphasize the role of these robots in streamlining operations. As warehouses increasingly adopt automation technologies, they face challenges that require careful integration of robotics into existing workflows.

However, the journey is not without hiccups. Many facilities struggle with adapting their processes to accommodate new robotic systems. It's essential to address these issues head-on for successful implementation. The future of warehousing lies in balance—leveraging technology while refining human-robot collaboration to achieve optimal results.

Emerging Technologies Shaping Material Handling Robots in 2026

As we look towards 2026, material handling robots continue to evolve rapidly. New technologies are emerging, drastically influencing the efficiency of warehousing operations. Autonomous mobile robots (AMRs) are becoming commonplace. These robots navigate through warehouses with increasing accuracy. They can transport goods and streamline workflows without human intervention. However, the implementation of these systems can face challenges. Many facilities struggle with integrating AMRs into existing layouts.

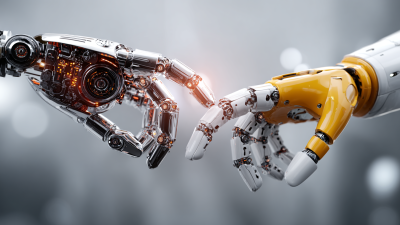

Another significant trend is the rise of collaborative robots, or cobots. Designed to work alongside human workers, cobots enhance productivity. They tackle repetitive tasks, allowing humans to focus on more complex activities. Yet, potential safety concerns arise. Ensuring these robots can safely interact with people is crucial. The feedback from workers on these interactions remains essential for continuous improvement.

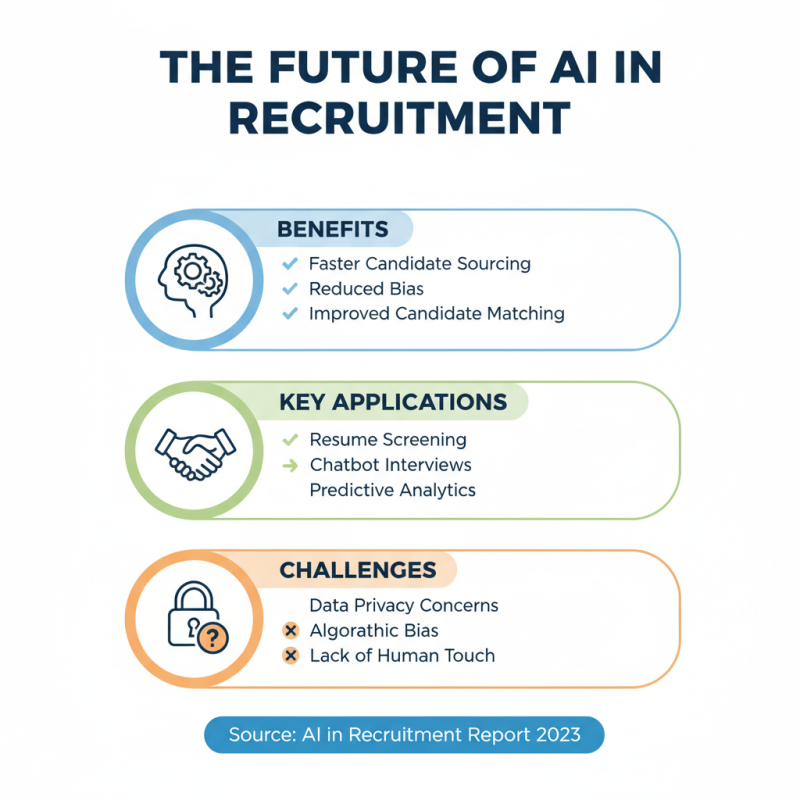

Artificial intelligence (AI) is also reshaping material handling. AI analyzes vast amounts of data to optimize processes. Predictive maintenance becomes a reality, reducing downtime. However, reliance on AI raises questions. What happens when systems fail? Understanding the limitations is vital for long-term success. Balancing innovation with practical considerations will be key in the coming years.

2026 Top Trends in Material Handling Robots for Efficient Warehousing

Key Features of Next-Gen Material Handling Robots for Warehousing

Next-gen material handling robots are transforming warehousing. These robots incorporate advanced sensors and AI. They can navigate complex environments with ease. Enhanced agility allows them to maneuver through tight spaces. This is crucial for maximizing storage efficiency.

Tips: Evaluate your warehouse layout. Identify areas where robots can enhance efficiency. Small changes can make a significant difference.

Another key feature is their ability to work collaboratively. These robots can communicate with each other. They optimize task allocation in real-time. This means faster processing and fewer delays. However, companies must train staff properly. Integration can be challenging.

Tips: Provide training sessions for employees. Understanding robot capabilities can lead to smoother operations. Ensure operators feel confident.

Finally, durability is essential. Robots must withstand harsh warehouse conditions. This includes temperature fluctuations and humidity. Regular maintenance can be overlooked, but it's critical. Robots can fail without proper care. Addressing these details can prevent costly downtime.

Tips: Schedule regular checks. Small repairs can save big in the long run.

Impact of AI and Automation on Efficiency in Warehousing Operations

The warehousing sector is witnessing a significant transformation due to AI and automation. Recent studies show that implementing AI-driven robots can increase productivity by nearly 30%. These systems streamline tasks like sorting and picking, allowing human workers to focus on complex duties. In today’s fast-paced environment, efficiency is paramount.

However, integrating automation isn't seamless. Some workers express concerns over job displacement. A report indicated that 60% of employees feel uncertain about their roles as robots take over repetitive tasks. Balancing technology with human labor is crucial.

Despite these challenges, the potential benefits are clear. AI can analyze data to predict inventory needs, reducing waste. Automation can also enhance accuracy, minimizing errors to just 1% in order fulfillment. This accuracy improves customer satisfaction and reduces operational costs. The evolution of material handling robots promises a new wave of efficiency, yet it requires careful consideration of the human aspect in warehousing operations.

Integration of Collaborative Robots in Material Handling Systems

The integration of collaborative robots in material handling systems marks a significant trend in warehousing. These robots operate alongside human workers, enhancing efficiency and safety. They can perform repetitive tasks, allowing humans to focus on more complex issues. Picture a warehouse where robots transport items smoothly. Workers can quickly pick and pack orders without interruptions.

However, this collaboration is not without challenges. Communication between robots and humans can be tricky. Misunderstandings may lead to delays. Training is essential to ensure everyone knows how to work together effectively. Moreover, the initial investment in technology and infrastructure can be high.

Despite these hurdles, the potential for improved productivity is clear. Collaborative robots adapt to changing tasks. They can even work in dynamic environments. As more companies explore this technology, it's vital to address the human-robot interaction aspects. Continuous feedback and adjustments can create a seamless working environment. This approach transforms warehousing into a more efficient operation.

Challenges and Solutions in Implementing Robotics in Warehousing

The integration of robotics in warehousing faces several challenges. First, workers may feel threatened by automation. This fear can lead to resistance among staff. Training is essential to alleviate these concerns. Educating employees on how to work alongside robots fosters a collaborative environment.

Infrastructure is another significant hurdle. Many warehouses have outdated layouts that do not accommodate autonomous systems. Retrofitting existing spaces requires time and investment. This can hinder the improvement of operational efficiency. Moreover, choosing the right technology often involves trial and error. Not every robotic solution fits all warehouse needs.

Another critical aspect is maintenance. Robots require regular upkeep to function efficiently. Delays in service can disrupt productivity. Therefore, robust support and training systems are vital. Additionally, data security must be prioritized. Cyber threats can compromise sensitive warehouse operations. Companies must stay proactive to protect their systems.

Balancing these challenges is crucial for successful robotics implementation in warehousing.

Related Posts

-

Why Are Material Handling Robots Essential for Modern Warehousing

-

Top 10 Robotic Automation Solutions You Need to Know?

-

Exploring the 2026 Top Trends in the Automation Industry

-

What is Robotics and Automation and How It Transforms Industries Today

-

Revolutionizing Efficiency: How the Automation Industry is Expected to Surge by 30% by 2025

-

How to Integrate Robotics and Automation for Enhanced Business Efficiency